Tackling challenges requires deep capabilities

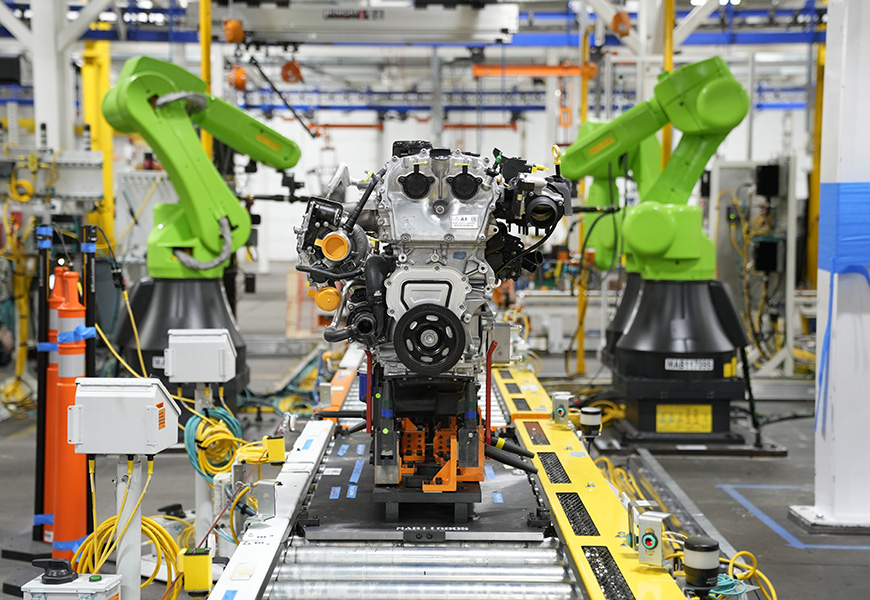

HTI Cybernetics has adopted a collaborative mentality, where humans and robots work together safely and effectively to enhance operations. By managing operations with less human interaction, your company can achieve greater productivity by automating tedious and physically demanding tasks. Our applications help to reduce the risk of human error while improving consistency and quality.

Our experts will partner with you to engineer custom solutions for the job at hand. Seamless integration and ease of programming minimize setup and training time. When needed, you can simply redeploy robotics for a wide range of tasks and applications. Finally, less infrastructure changes reduce operational costs. All of which are good news for your bottom line.

Tasks & Applications

Adhesive & Sealant

Ensure precision, accuracy, and quality control.

Fastening & Joining

Easy, efficient, and economic fabrication of product.

Automated Assembly

Lowers production costs while improving quality efficiency.

Weld Automation

Delivers faster processes and higher quality of work.

Inspection & Test

Standardize inspection processes and reduce part errors.

Key Applications

Assembly

Optimize workflows and productivity with seamless integration.

Dispensing

Proper design ensures accuracy and error prevention.

Finishing

Skilled tradesman deliver high quality finishes.

Machine Tending

Improve speed and process quality while reducing the risk of injury associated with working in close proximity to heavy machinery.

Material Handling

Minimize the risk of operator fatigue and injury.

Welding

More consistent, high-quality welds.

Material Handling/Removal

Optimize operations through the ability to transport material quickly and efficiently.

Quality Inspections

Ensures a safe and compliant work environment.